31

May

TFT AD Series: Adsorption Dehumidifiers

TFT AD series: The professional range of adsorption dehumidifiers

What are adsorption dehumidifiers?

Adsorption dehumidifiers are high-performance equipment designed to control humidity in highly demanding situations, equipped with a silica gel desiccant rotor and designed for installation with air ducts. These dehumidifiers allow reaching very low dew points (-30oC), with negative process temperatures and a dry air output of less than 10% RH. Indicated when air humidity lower than 40%RH is required.MAIN FEATURES

APPLICATIONS

Production processes, product drying and pharmaceutical

AIRFLOW

Up to 3,100 M3/H

EXTRACTION CAPACITY

Between 0.59-18.9 KG/H

Production processes, product drying and pharmaceutical

AIRFLOW

Up to 3,100 M3/H

EXTRACTION CAPACITY

Between 0.59-18.9 KG/H

AD100 SERIES - 1250E

The small AD100-1250 series incorporates main switch, manual/automatic selector, ammeter, hour meter, potentiometers to regulate air flow and connector for remote control.

Accessories

AR247 humidity and temperature controller.

Optional

Remote alarm signaling.

STAINLESS STEEL 304 version.

AD1000 SERIES - 3100T

They are highly efficient and customizable equipment. They incorporate a control PLC, with a control touch screen, which allows the management of humidity, system operating parameters, alarms and communication through a Modbus and TCP/IP gateway to be able to integrate the equipment in a simple way.

Accessories

KAVTF-I humidity and temperature controller.

Optional

Version with heat recovery.

STAINLESS STEEL 304 version.

Steam Regeneration.

Pre/post cooling water coil.

3-way proportional pre/post cooling valve.

Filter alarm.

Fans with variable frequency.

Full climate control version (humidity and temperature).

Download the sheets here

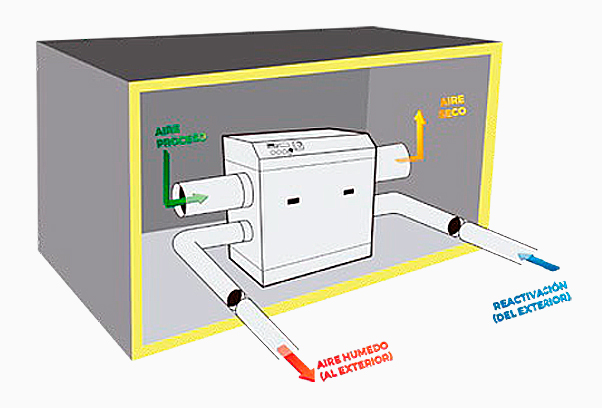

OPERATION OF THE DEHUMIDIFIER

A fan drives the process air through the silica gel rotor, eliminating humidity from the air. Another fan (reactivation) allows the regeneration of the rotor and extraction of humid air to the outside.

The dehumidifier is made up of the following functionality:

• Silicagel desiccant rotor.

• Electrical reactivation by PTC resistors.

• Reactivation with steam or gas.

• External ON/OFF or proportional control signal.